Airport pavement maintenance using the Traffic Speed Deflectometer (TSD)

Runways suffer a great deal of wear and tear, simply as a result of normal operations. Maintaining those surfaces with minimal disruption to flights is part of any airport’s responsibility to its users and a major challenge. Any defects or damage to the runway can lead to accidents, injuries, or even fatalities.

Environmental and climate-related factors such as changes in temperature or harsh winter weather can affect airport pavements, as can the natural deterioration of the materials used in their construction.

The main impact of aircraft on runways is caused by their weight and braking, which causes reflective cracking over time. Besides cracking, other types of damage that can occur include joint seal damage, distortion, disintegration and loss of skid resistance.

Effective runway maintenance is not only essential for safety and operational efficiency but also for cost-effectiveness. Timely detection and remediation of pavement defects through TSD surveys help prevent costly runway repairs and premature replacements. By implementing proactive maintenance strategies based on TSD data, airports can extend the lifespan of their runways and areas in the entire airport, optimize maintenance budgets, and minimize long-term operational costs associated with runway downtime and emergency repairs.

Why measure airfields with a Traffic Speed Deflectometer?

The TSD is a well-proven Rolling Wheel Deflectometer measuring pavement response to an applied load. The unique TSD technology is developed by Greenwood Engineering and has initiated a shift of paradigm in global pavement and runway engineering compared to the Falling Weight Deflectometer (FWD) or the Heavy Weight Deflectometer (HWD).

While driving at normal traffic speed (up to 80 km/h) the TSD provides continuous bearing capacity results at project and network level. High mobility allows for accurate measurements during normal daytime operation of the. Furthermore, it is operated by only one driver and one operator. All this makes the TSD highly cost-effective.

All the data from the TSD enables authorities to identify areas of weakness and prioritize maintenance efforts to prevent structural failures, not only for the runways but the entire airport including parking areas.

Benefits of TSD measurements

- High measuring speed

- High productivity

- Can measure during normal airport operation

- High spatial resolution

- Continuous measurements

- Highly repeatable

- Measures on asphalt and on concrete

- Find small weak areas

- Full overview of bearing capacity

- Measures response to moving load

- Realistic effect of inertia

- Realistic effect of viscoelasticity

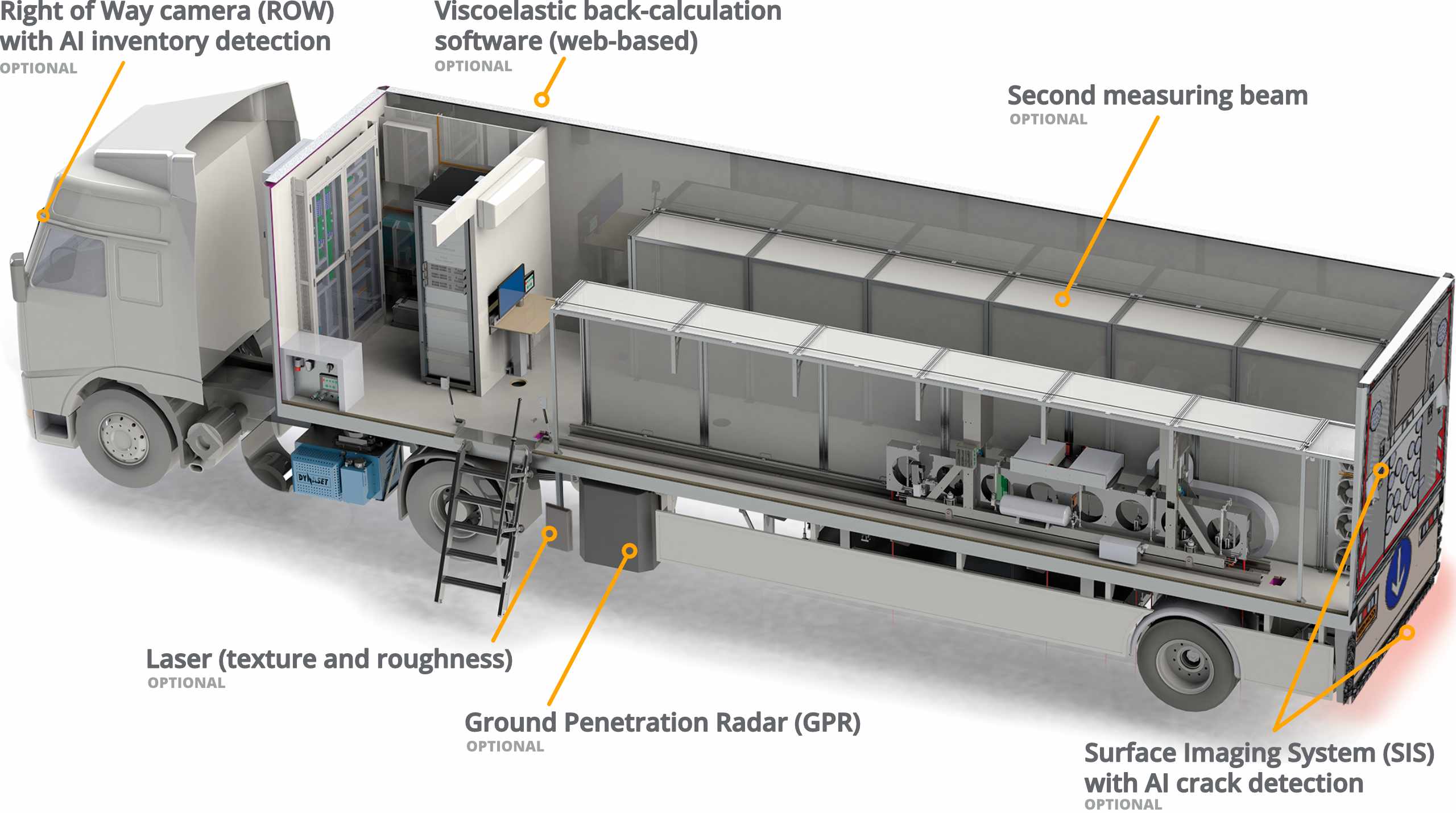

Besides the GPR it is possible to include optional equipment as Surface Imaging System (SIS), Right Of Way Camera (ROW) etc. for collection of a full set of synchronised road data in one drive.

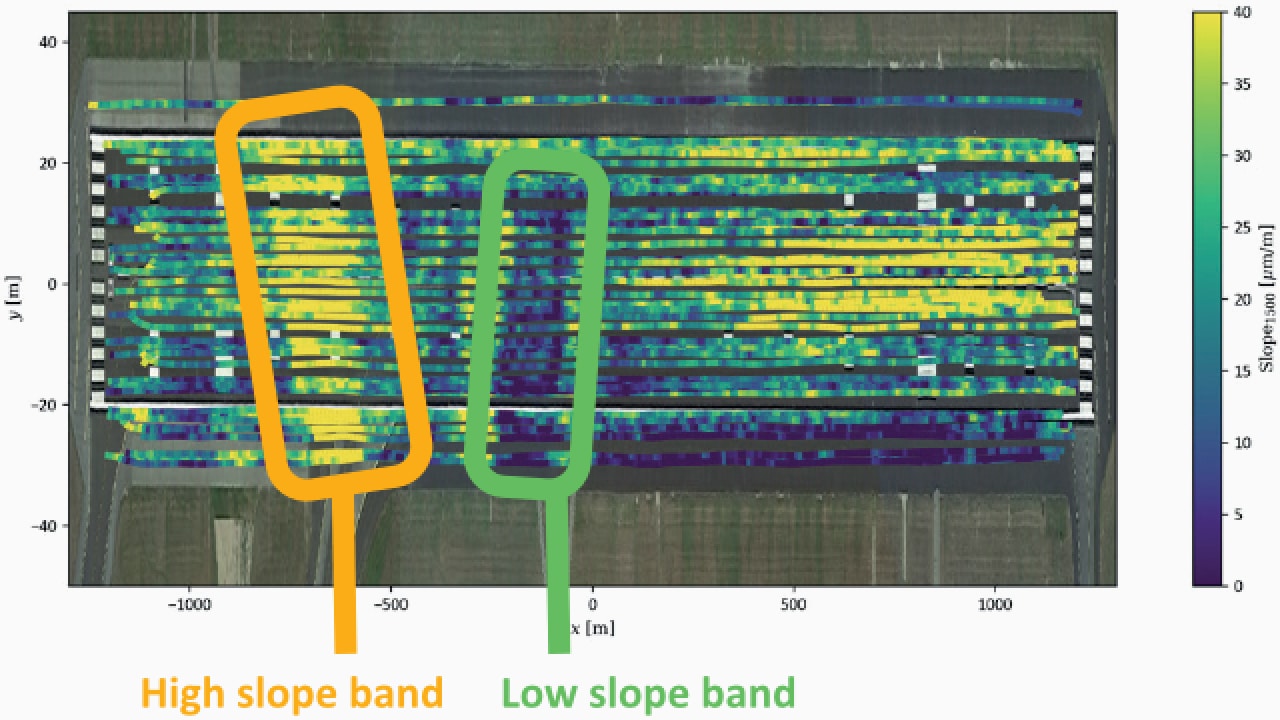

Measurering examples from runway:

Slope in 1.5 m

The TSD finds weaknesses in the lower subgrade layers related to the subgrade geological features.

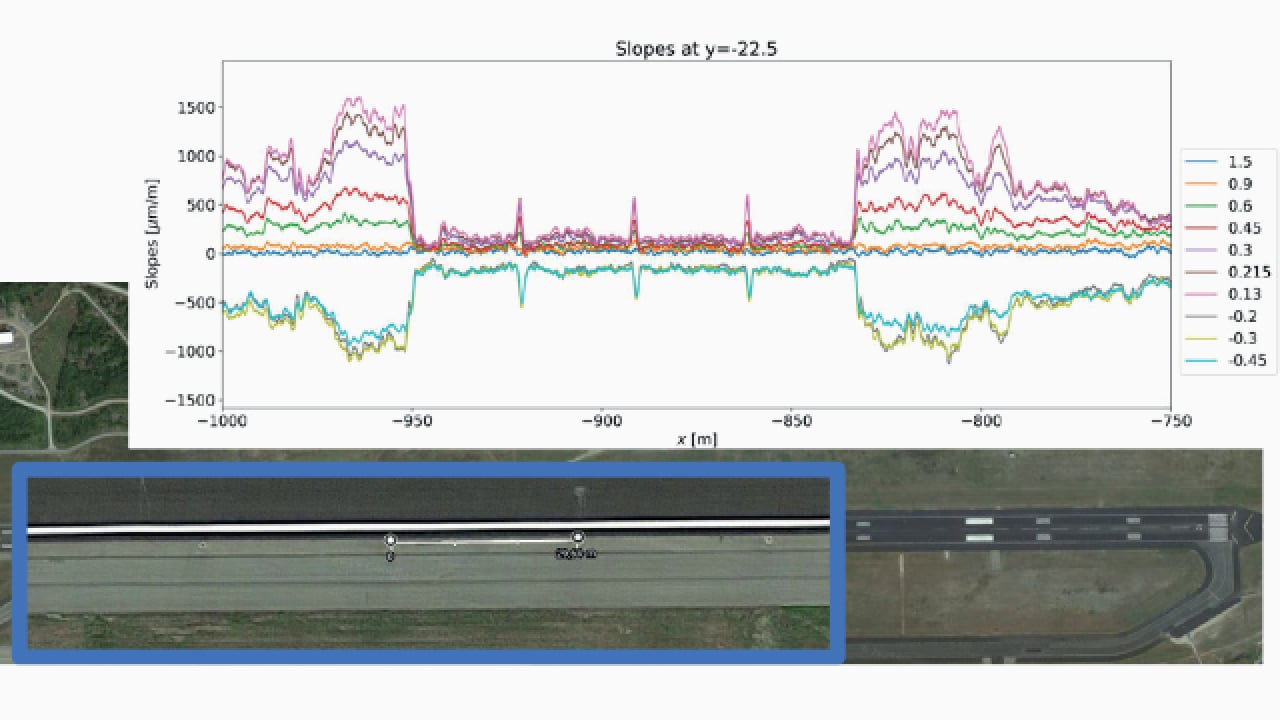

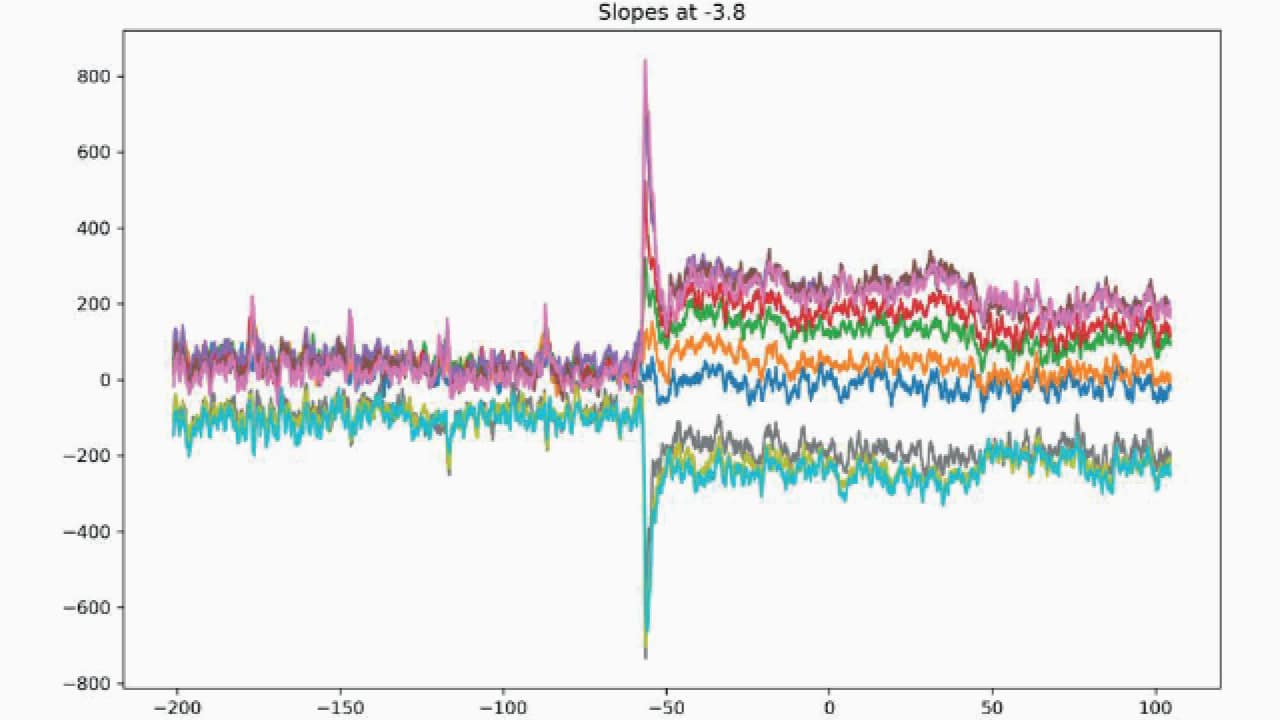

Measurering examples from runway:

Slope spikes on runway

Finds small weaknesses in the upper asphalt layer. The TSD is able to consistently pick up the same feature.

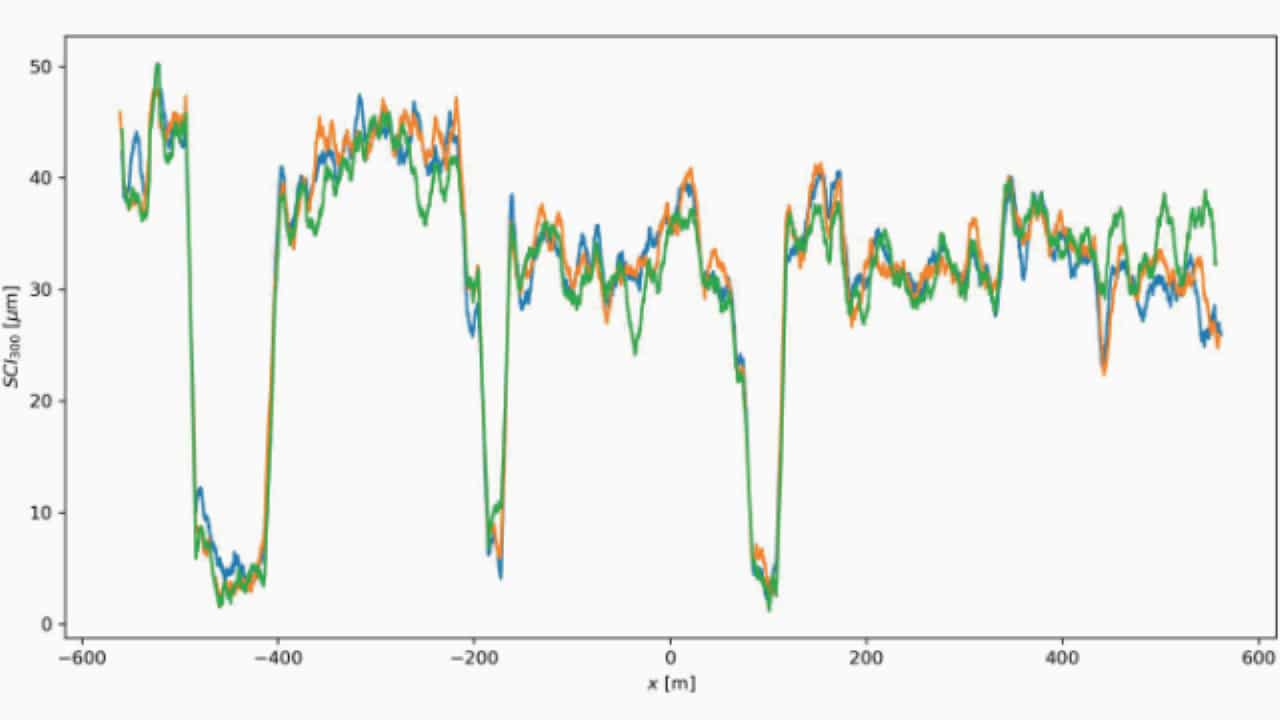

Measurering examples from around terminal buildning:

Repeated SCI

3 measurement loops around terminal building shows a very high repeatability.

Measurering examples from parking lot:

Measurements on concrete

The TSD finds good and poor load transfer between slaps. Transition between original and reinforced pavement is clearly seen. Measured on concrete under asphalt.